Reinforced concrete is a staple in modern construction. Its strength and durability depend heavily on one crucial factor: the tensile strength of the steel reinforcing bar (rebar) within. Tensile strength, simply put, is a material’s ability to withstand pulling forces without breaking. This comprehensive guide delves into the intricacies of tensile strength, explaining its significance, influencing factors, and its critical role in ensuring the structural integrity of buildings and infrastructure.

What is Tensile Strength?

Tensile strength measures a material’s resistance to fracture when subjected to a pulling force. Imagine stretching a rubber band. The force you apply is tensile stress. The rubber band resists this stress up to a point. This resistance is its tensile strength. Once the applied stress exceeds the tensile strength, the rubber band breaks.

We measure tensile strength in units of force per unit area, typically megapascals (MPa) or pounds per square inch (psi). A higher MPa or psi value indicates a stronger material, capable of withstanding greater tensile stress before failure.

Why is Tensile Strength Important?

Tensile strength is a fundamental property with numerous applications across various industries. Consider these examples:

- Construction: Tensile strength dictates the load-bearing capacity of steel beams in bridges and buildings. Reinforcing bar (rebar), embedded in concrete, relies on its tensile strength to resist cracking and ensure structural integrity.

- Manufacturing: From aircraft cables to car parts, manufacturers select materials with appropriate tensile strengths to withstand operational stresses and prevent failures.

- Product Design: Engineers consider tensile strength when designing everyday products like plastic bags, ropes, and furniture, ensuring they resist tearing and breakage.

Understanding tensile strength is crucial for:

- Material Selection: Choosing materials with appropriate tensile strengths ensures products and structures perform safely and reliably under expected loads.

- Design Optimisation: Engineers optimise designs to minimise material usage while maintaining adequate tensile strength, resulting in cost-effective and efficient solutions.

- Predicting Failure: Tensile strength data helps predict how materials will behave under stress, enabling engineers to design against potential failures and ensure safety.

Factors Affecting Tensile Strength

A material’s tensile strength isn’t a fixed value. It can change based on various factors, including:

- Material Composition: The types of atoms and their arrangement within a material significantly impact its strength. For example, steel, an alloy primarily composed of iron and carbon, boasts higher tensile strength than pure iron.

- Temperature: Generally, heating a material weakens the bonds between its atoms, reducing its tensile strength. Conversely, some materials, like certain plastics, become stronger at lower temperatures.

- Grain Size: Most metals are composed of microscopic crystals called grains. Smaller grain sizes typically lead to higher tensile strength due to increased grain boundary area, which hinders deformation.

- Strain Rate: Rapidly applied stress, such as a sudden impact, can result in different tensile strengths compared to slowly applied stress.

- Work Hardening: Deforming a material through cold rolling or forging can increase its tensile strength by altering its internal structure.

- Environmental Factors: Exposure to corrosive environments, high humidity, or ultraviolet radiation can degrade certain materials over time, reducing their tensile strength.

Measuring Tensile Strength

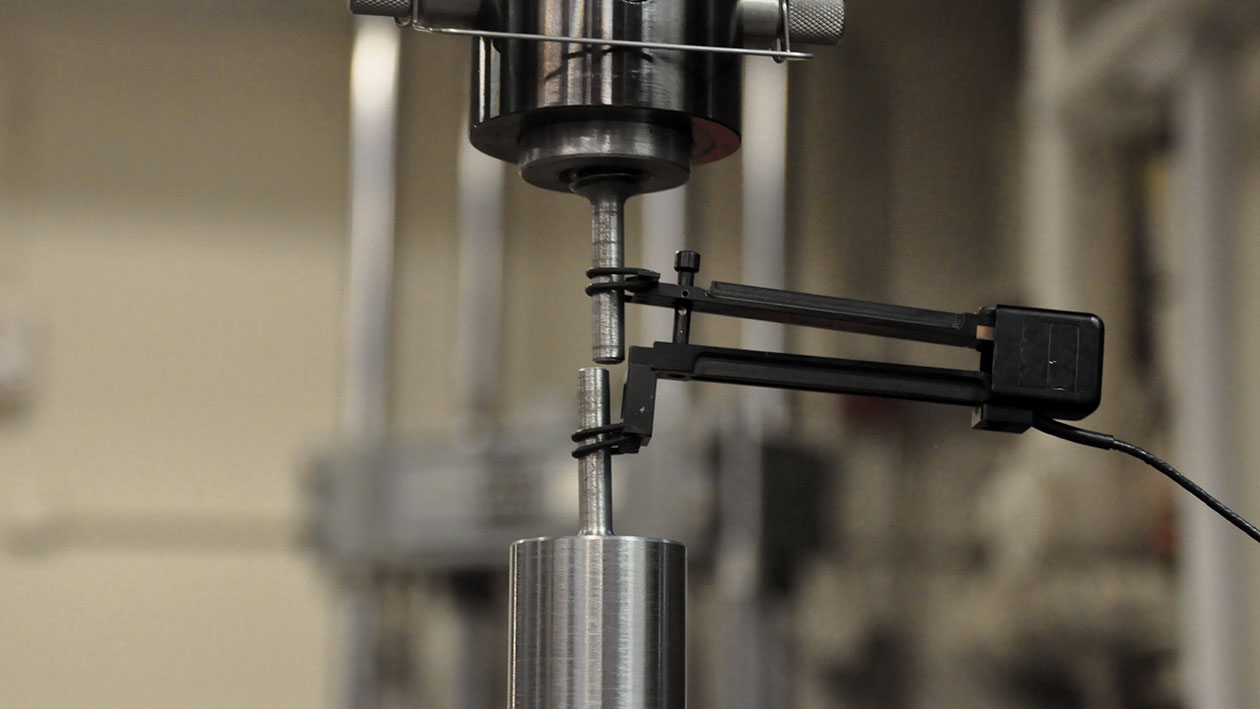

Engineers determine a material’s tensile strength through a standardised test called a tensile test. Here’s a simplified overview of the process:

- Sample Preparation: Technicians carefully prepare a sample of the material, typically in a standardised shape like a dogbone, with a narrower central section.

- Testing Machine: They secure the sample within a tensile testing machine, which applies a controlled pulling force (tension) along its axis.

- Data Recording: The machine precisely measures the sample’s applied force and elongation (stretching) throughout the test.

- Fracture Point: The test continues until the material reaches its breaking point.

- Results Analysis: Engineers analyse the recorded data to determine the material’s tensile strength, typically at the point of yielding (where it starts to deform permanently) or ultimate tensile strength (the maximum stress before fracture).

We can express tensile strength mathematically as:

Tensile Strength (σ) = Maximum Tensile Force (F) / Specimen Cross-Sectional Area (A)

In simpler terms, tensile strength is calculated by dividing the maximum force required to break the specimen by the original cross-sectional area of that specimen.

Tensile Strength of Rebar

The tensile strength of rebar is the maximum stress that the reinforcement bar can endure when being elongated. This is a crucial factor in nonlinear designs, where the rebar’s capacity to bear stress without failure is fully utilised.

Grades and Strengths

Within Australia, reinforcing steels are classified using the following gradings:

- Deformed Grade 250N

- Deformed Grade 300E

- Deformed Grade 500L

- Deformed Grade 500N

- Deformed Grade 500E

- Plain Grade 250N

- Plan Grade 500L

- Plain Grade 300E

- Plain Grade 500E

- Plain Grade 500N

- Right-hand-threaded grade 500E

The tensile capacity of rebar is calculated using the formula: F = Φ × As × fy

where F is the tensile capacity, Φ is the material reduction factor, As is the area of steel, and fy is the yield strength of the reinforcing steel. For instance, using a yield strength of 435 N/mm² and a reduction factor, the tensile capacity for a set of rebars can be calculated accordingly.

Is Higher Tensile Strength Always Better?

While it might seem intuitive that higher tensile strength is always better, the ideal tensile strength depends entirely on the specific application and desired material properties. A material exceptionally strong in tension might be brittle or costly to produce, making it unsuitable for some purposes. Factors like impact resistance, flexibility, weight, and cost must be weighed alongside tensile strength to determine the best material for a given application. Engineers carefully balance these factors to ensure optimal performance and safety.

What Is the Difference Between Breaking Strength and Tensile Strength?

Although often used interchangeably, “breaking strength” and “tensile strength” have a subtle yet important distinction in engineering contexts. Tensile strength refers to the maximum stress a material can withstand before permanent deformation, measured in units like megapascals (MPa) or pounds per square inch (psi). It represents a material’s inherent resistance to being pulled apart. On the other hand, breaking strength describes the actual force required to fracture a material under tension, measured in units like Newtons or pounds.

While tensile strength focuses on the material’s internal resistance, breaking strength considers the real-world force needed to cause failure in a specific sample, accounting for factors like the sample’s dimensions and testing conditions.

Tensile stress on the other hand can occur in concrete because of shrinkage.

What Material Has the Highest Tensile Strength?

The material with the highest tensile strength is multiwalled carbon nanotubes, which have been measured to have a tensile strength of up to 63 GPa, although this is still below their theoretical limit of 300 GPa [4]. However, no macroscopic object made from carbon nanotubes has achieved tensile strength values close to this figure.

Among pure metals, tungsten has the highest tensile strength, with an ultimate tensile strength of around 980 MPa [1][3]. Tungsten is known for its high melting point and strong metallic bonds, which contribute to its high tensile strength. However, it is brittle in its pure form, making it less suitable for applications requiring toughness [1][3].

In terms of commercially available materials, high-strength steel alloys and carbon fiber composites are often used for their high tensile strengths. Some steel alloys can reach tensile strengths of over 2 GPa [2].

Citations:

[1] https://readingplastic.com/which-metal-has-the-highest-tensile-strength/

[2] https://www.reddit.com/r/AskEngineers/comments/wi7dbr/what_commercially_available_material_has_the/

[3] https://industrialmetalservice.com/metal-university/what-metal-has-the-highest-tensile-strength/

[4] https://monroeengineering.com/assets/guides/monroe-tensile-strength.pdf